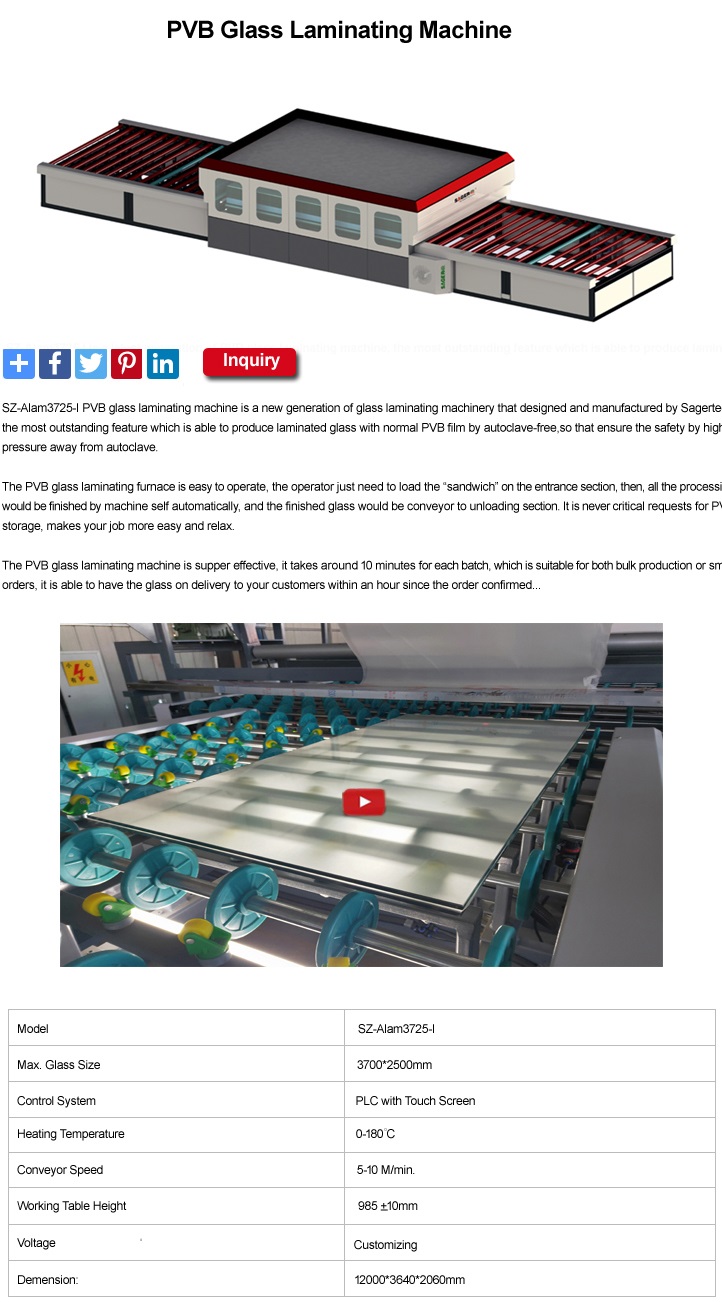

SZ-ALAM-3725-II PVB glass laminating furnace is a professional equipment to produce laminated glass without autoclave. It is able to produce various laminated glass thanks to the advantages of this machine. Its workable for with normal PVB film perfectly without autoclave. The processing is controlled through Siemens PLC , all the parameters would be set easily by touch screen. PID output ensure an accurate temperature. The glass is conveyor to furnace with frequency motor. The machine is very easy to operate, just need to load glass on the entrance section, all the processing would be finished by machine self automatically, and the finished glass would be conveyor to unloading section.

The furnace is well working with PVB film with high production capacity, the glass would be conveyor to furnace continuously, and around 10-15 minutes for each batch, so that is able to have bulk production or single pieces. Full automatic running, the operator just need to load the assembled glass on loading table, and take off the finished glass from unloading table, all the other jobs would be well done by the machine automatically. Saving labor, but high production efficiency

Features:

- Workable with both normal PVB film without autoclave

- Completed autoclave-free, no need the climate room to control humidity

- The processing would be finished automatically by computer control

- Each 10 minutes/production cycle

- Very flexible for production, suitable for both bulk and single piece

|

Model |

SZ-Alam3725-II |

|

Max.Glass Size |

3700*2500mm |

|

Control System |

PLC with touch screen |

|

Heating Temperature |

0-160℃ |

|

Conveyor Speed |

5-10 米/分钟 |

|

Working table Height |

985±10mm |

|

Voltage |

Customizable |

|

Demension |

16000*3600*2100 |