1. Horizontal structure, simple and perfect appearance design;

2. There is a stainless steel tank in the input section, the rubber roller can perform automatic cleaning , and the pre-cleaning system is equipped with high-pressure water jet which can remove the most of dusts before enter into the machine, so that can keep the water be cleaning.

3,Equipped three pairs of brushes , the front of a pair of hard brush can be cylinder lift;The third pair of special soft bristle brush rollers can be used to clean the ordinary coating film.Hard LOW-E glass and sunlight coated glass;

4. Transmission adopts gear transmission, which is stable and reliable.Transmission using frequency conversion speed, digital display, easy to control.More conducive to connection, double edge grinding production line, glaze line, insulating glass production line, safety glass production line;

5. Adopt advanced technology of multi-stage air outlet blade, equipped with a pair of straight air knives and a pair of oblique air knives, energy saving and high efficiency;

6, electric control cleaning section shelf and air drying section shelf overall rise and fall, the internal maximum opening can reach 450mm, easy maintenance and inspection.Digital display of clean glass thickness, can be precisely adjusted and observed;

7. The efficient cleaning and drying machine with the speed of 12 meters per minute can be customized according to customer requirements.Double fan structure can be customized.

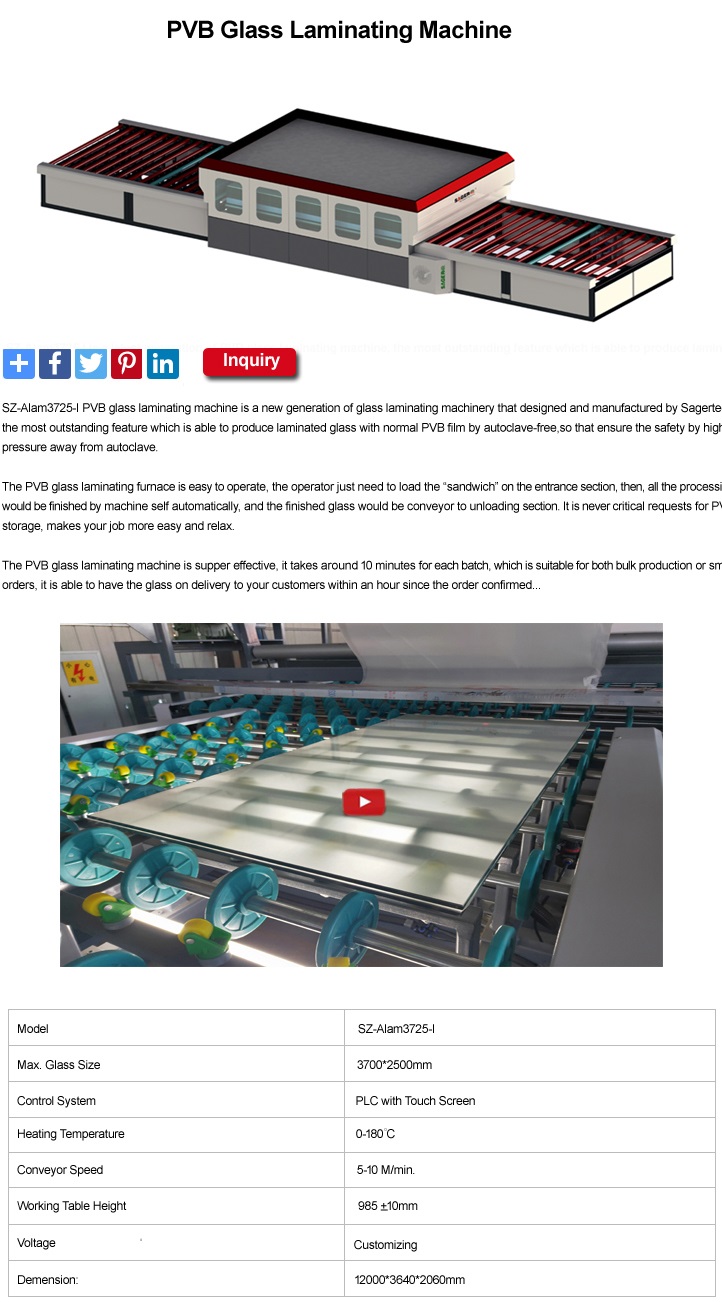

Model

| Model |

SZ-W33 |

|

Max. Glass Width |

3300mm |

|

Min.Glass Size |

400*400mm |

|

Glass Thickness |

3-25mm |

|

Working Speed |

5-14M/Min. |

|

Brushes |

3 pairs |

|

Air Knife |

2 pairs |

|

Power |

45KW |

|

Weight |

4500KG |

|

Dimension |

5550*4400*2850mm |