This article discusses the benefits of using Sagertec. glass laminating system, which are autoclave free and can produce a wide range of decorative and architectural glass products. - Glass laminating system are used to produce EVA and PVB glass lamination, which is a versatile product that can be used to produce architectural laminated glass, safety glass PVB glass, EVA glass and other products such as tempered laminated glass, glass fabric laminated glass, and even bulletproof laminated glass. Sagertec. autoclave free machines use a PVB interlayer to make high quality end products from paper, plastic film, mesh switchable film or PVB. The autoclave free machine is faster than traditional methods of laminating which results in less energy consumption and lower costs for the customer. In addition to the cost savings associated with this technology it also provides improved safety due to the elimination of potential explosion hazard.

The non autoclave Glass Laminating Machine is designed to produce PVB laminated glass with ordinary PVB interlayer. Its design allows for multiple layers of PVB to be achieved to the desired thickness for various glass production needs.

Autoclave free glass laminating machines are a great feature for the glass laminating industry. It is a type of autoclave free equipment that is used to vacuum laminating. The machine uses optimized cycle processing to achieve maximum production efficiency and can perform Sagertec line of virtually any manufacturers requirements in accordance with PVB, EVA and other materials.

Sager glass technology offer the same level of reliability and functionality as a traditional autoclave system, but without the need for an autoclave. The machine allows for the implementation of safety and decreased energy costs, as well as increased production levels, which can help any organization achieve their desired results. With this glass machine, customers can expect to achieve shorter cycle times with minimal material waste.

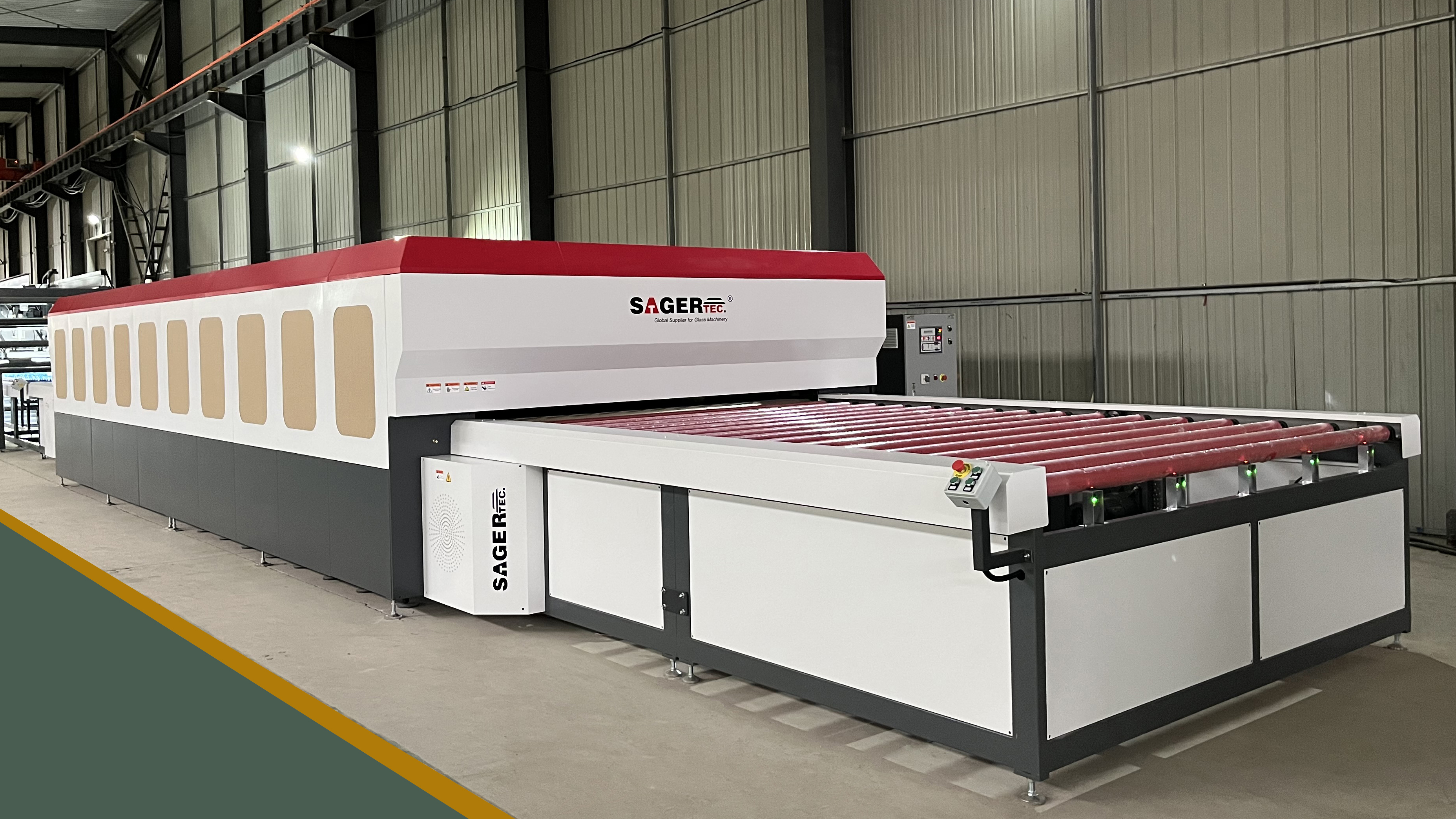

SAGERTEC. vacuum lamination system that is versatile and powerful. It utilizes unique heating system for the production line, to provide an exclusive heating process. This process involves extended heating of the environment that has been optimized to offer lower energy costs.Sagertec has brought this vacuum laminator to market with its unique heating system, which provides excellent temperature control and consistent results. The company has also redesigned virtually all aspects of existing laminating technology by introducing its own technology into the mix.

This Autoclave Free Glass Laminating furnace produces thinner interlayer glass with a thickness of 1.2mm and an adjustable heated vacuum chamber that helps to prevent air from leaking. In addition, it can be used to do lamination work for decorative glass, walls, canopies, various flat lamination, and put assembly glass. The machine is also equipped with pointed support walls that ensure layers are evenly distributed while a silicon blanket is used to provide further security applications.